Triangle Electronic Services offer a full electronics manufacturing capability:

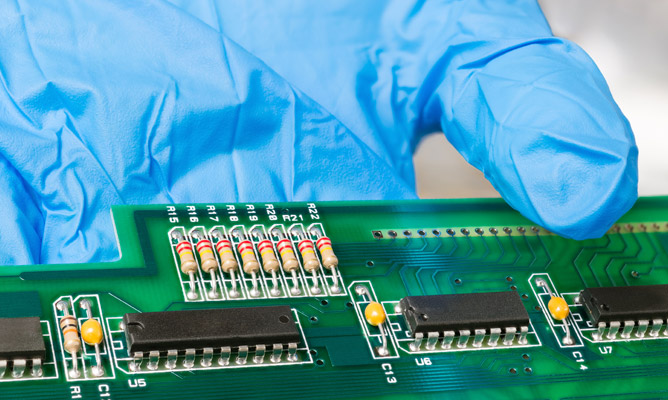

Automated PCB Assembly

Triangle Electronic Services has many years experience in PCB assembly. The component placement capability utilizes 4 surface-mount lines, each with multi-zone reflow, catering for all common package types;

• Package size to 0201

• QFP

• BGA and Micro BGA

• CSP

• Flip Chip

• CGA and LGA

Electro-Mechanical Assembly

Triangle Electronic Services’ integration department has a wealth of experience in the manufacture of electro-mechanical assemblies.

• Sub-assemblies

• Chassis wiring

• Box-Build

• Full product build

• System integration

Triangle has long established links with supply-chain partners providing high quality and reliable parts, such as custom-metalwork, moulded-plastics, enclosures, racks and chassis components.

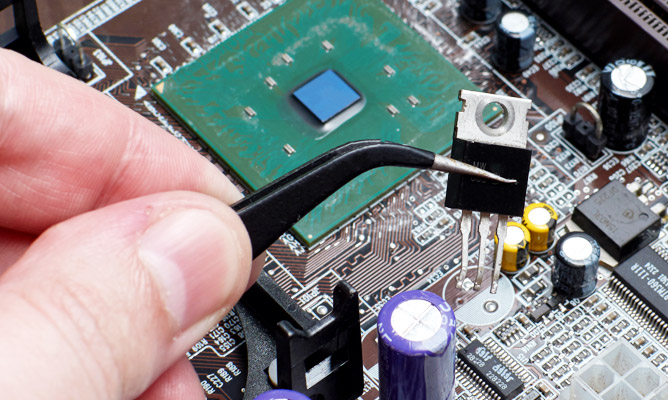

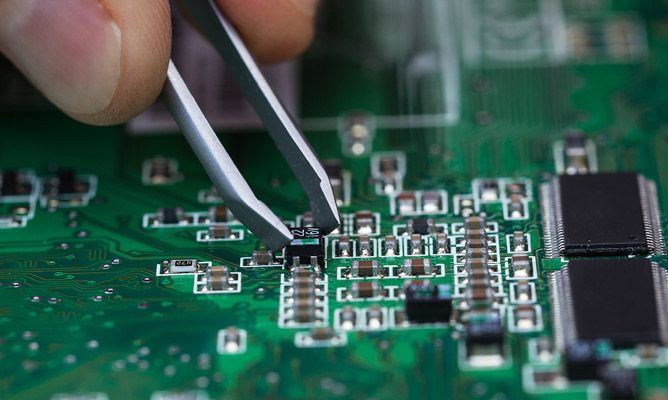

Hand Assembly

Complementing the flexibility and capacity offered by the automated surface mount lines, Triangle Electronic Services has a dedicated hand assembly manufacturing department, with a team of experienced and highly trained operators, whose eye for detail ensure the highest standards of workmanship.

• Component Preparation and Pre-forming

• Dedicated leaded and non-leaded capability

• Wave and Hand Solder

In addition to the conventional PCB assembly capability, Triangle Electronic Services has experience in working with different technologies and materials:

• Flexible PCB’s

• Flex-Rigid

• Insulated Metal Substrate (Aluminium)

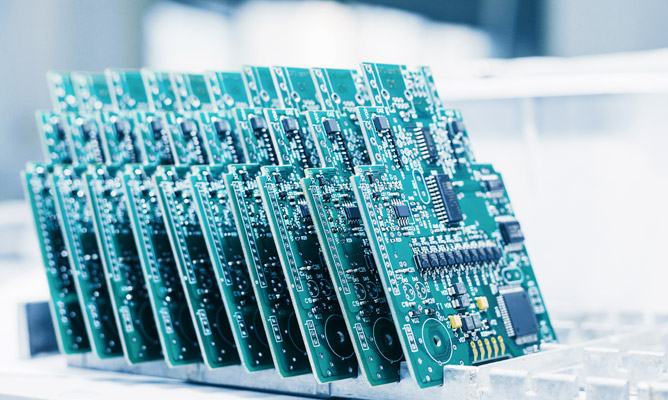

Test and Inspection

By utilising industry workmanship and inspection standards, complemented by our technically-capable and experienced Test Department, Triangle Electronic Services ensure that every customer’s product reaches its respective markets reliably manufactured and fully tested.

• Automatic Optical Inspection (AOI)

• Qualified Inspectors to recognised industry standards

• Ersascope inspection for BGA devices

The capability of the Test Department allows for all levels of customers’ test requirements.

• Board Level In-Circuit

• Finished Product Functional Test

• Custom Test Development

Cable Assembly

Triangle Electronics Services is experienced in the manufacture of cable assemblies in most termination types:

• IDC

• RF

• Co-axial

• Crimp

• Wire Wrap

In addition to simple, stand-alone cable assemblies more complex looms and wire harness can also be catered for.

Repairs and Rework

To support product life-cycles, Triangle Electronic Services offers an after-sales repair and rework capability to its customers.

• Repairs and Rework

• BGA Removal and Replacement• Ersascope inspection for BGA devices

• Upgrades and Modifications

• Fault Finding